JANIsoft machine control

Machine control for rapid processing

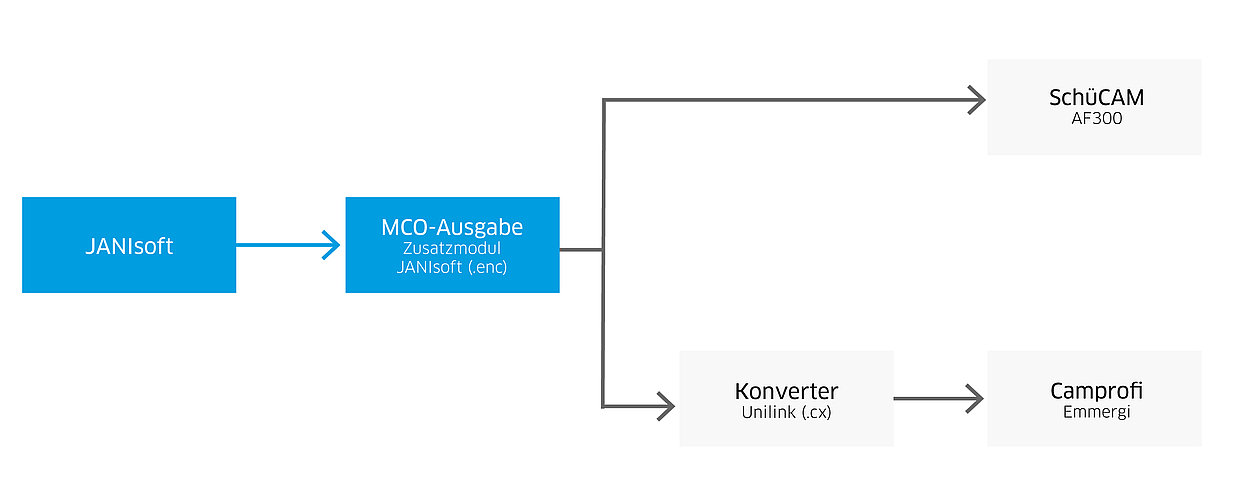

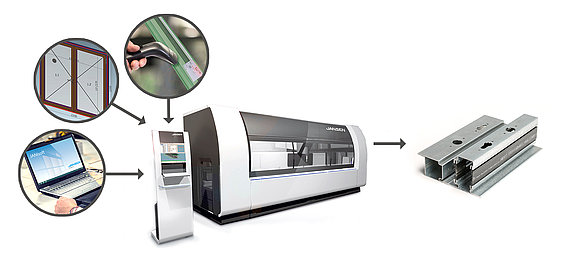

You can process a selection of steel systems with the new JANIsoft machine control. The processing data is transmitted to the machines in a data exchange file. All profile processing activities can be displayed in advance in 3D processing mode and can be adjusted to suit the customer's requirements at an early stage. The intended processes can be checked in advance using JANIsoft in the office or on the production floor. Jansen metalworking machine control supports different saw types and profile machining centres

Optimum interaction with just one data exchange file, which can be directly used and processed on the machine.