Jansen

https://www.jansen.com/en/index.html

CO₂-free for the future

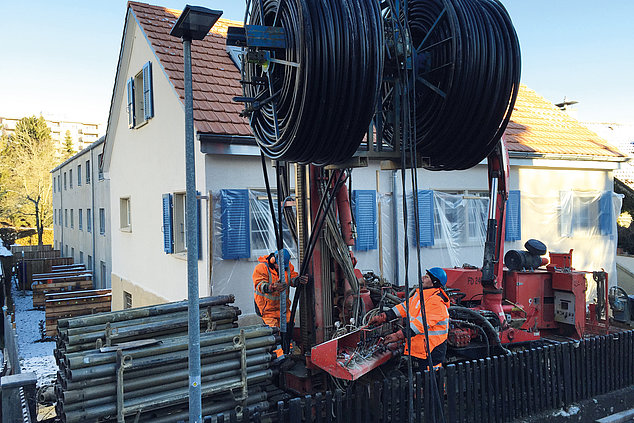

BaseLink, which opened in summer 2022, is a technology hub offering a state-of-the-art work environment for start-ups and established companies in Allschwil. As a visionary location, innovation is anchored at the core of the site covering 75,000 m². The broad energy concept also includes geothermal energy. In this concept, large heat pumps are fed with geothermal energy – the probe field also serves as a thermal reservoir. The complete probe field was designed to be diffusion-tight, with high-performance geothermal probes.

Project details

Ambit

Supply systems

Geothermal systems

Supply systems

Geothermal systems

- Landowner

Bürgerspital, Basel/CH

- Owner Energy System & Contractor

Primeo Energie, Münchenstein/CH

- Specialist planning

Schädle GmbH, Basel/CH

- Drilling company

Barmettler Erdenergie, Moosleerau/CH

- Heat pumps

Walter Wettstein AG, Gümligen/CH