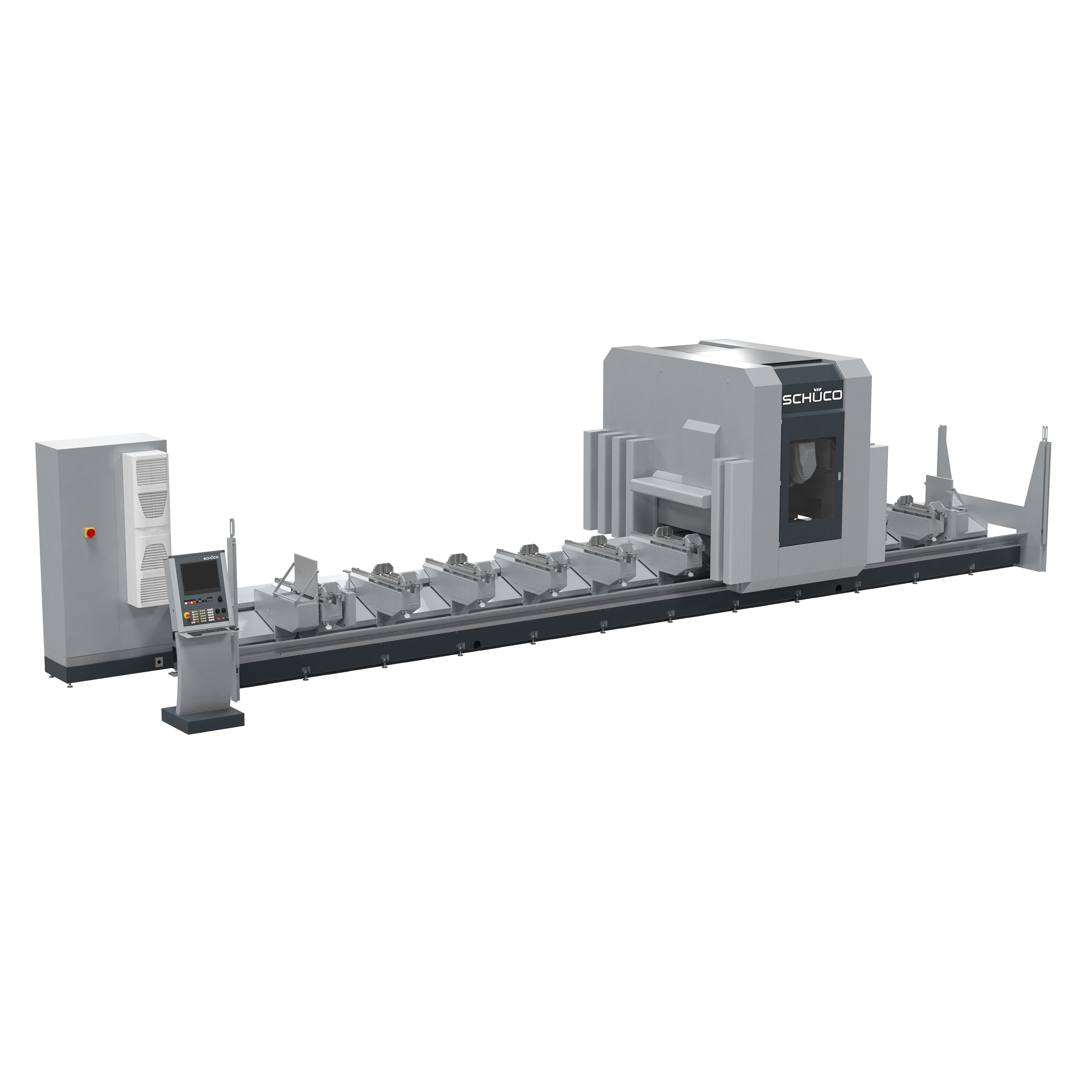

CNC-AF 500

With maximum CNC performance and a degree of flexibility and accessibility that is unique in the market, the AF 500 is the sound choice for virtually every metal fabrication task. The highly efficient machine design, intelligent controls and first-class drive and motor technology allow maximum speeds and precision to be achieved during machining. The AF 500 is complemented by an extensive range of solutions for IT integration. With these innovative, forward-looking solutions, the AF 500 guarantees maximum productivity and availability. The Schüco AF 500 features 6-sided machining and is an efficient processing machine for aluminium and steel profiles. The range of travel is sufficient to accommodate machining lengths of up to 7850 mm, including pre-head processing of up to a maximum of 7300 mm. The AF 500 is specially designed for processing window, door, facade and special profiles made from aluminium or steel.

- 5-sided machining of aluminium and steel profiles

- 6-sided machining of aluminium profiles can be done using an angled head

- Steel profile machining (S235 up to about 5 mm wall thickness)

- 16 kW spindle output

- Full torque from 1 − 9000 rpm

- Remote maintenance software allows Schüco's customer services staff to diagnose faults on the machine remotely (Internet connection required)

- High-resolution absolute position measuring systems

- X axis positioned by tempered, helical-toothed drive gear rods with servo motor

- Y and Z axes positioned by ball screw with servo motor

- Infinitely adjustable pivoting of the A and C axes by servo axis

- Measuring stop for measuring profile lengths

- Measuring device for measuring profile heights

- 8 individually driven, positionable clamps

- Automatic central lubrication system, SPS controlled

- Air-conditioning unit to cool electrical components in the control cabinet

- Control panel with 19“ Touch TFT colour display

- Welded machine bed provides the required strength and rigidity

- Toughened and ground track guideways

- Swarf collector drawers under processing area

- Paint finish: RAL 9006 (white aluminium), RAL 7016 (anthracite grey

Operation and control

- Easy-to-use operating panel with 19“ Touch TFT colour display

- Simple manual control using hand-operated unit

- SchüCam used for machine control

- Windows® is the common operating system for SchüCam and SchüCal

- The machine is supplied with the software installed

- Processing data for the AF 500 can be generated directly in the design and calculations software package JANIsoft

- Extensive macro library for Schüco profile systems

- SchüCam can be used on an ordinary office PC

- The SchüCam software is operated on the machine in the same way as on the office PC

- SchüCam with visualisation of the profiles, tools and the processing to assist with monitoring on both an office PC and on the machine

- Quick and easy transfer of machining data by CD, USB or over the network

- Simple, menu-guided modification of processing macros without NC programming knowledge

- In-house programming without the need for NC / CNC knowledge

- Regular software updates

- Remote maintenance software